Surface Interface Testing

- Products

- Petroleum & Oil Testing

- Flash Point Tester

- Engler Viscometer

- Water Content Tester

- Kinematics Viscometer

- Distillation Tester

- Density Tester

- Rust & Corrosion Tester

- Sulphur Content Tester

- Acid & Alkali Tester

- Dropping Point Tester

- Demulsibility Tester

- Aniline Point Tester

- Ash Content Tester

- Low Temperature Tester

- Residue Carbon Tester

- Existent Gum Tester

- Vapor Pressure Tester

- Oxidation Stability Tester

- Foaming Characteristic Tester

- Bomb Calorimeter

- Octane & Cetane Analyzer

- Other Tester

- Tablet Drug Tester

- Dissolution Tester

- Disintegration Tester

- Tablet Hardness Tester

- Friability Tester

- Multi-Purpose Tester

- Clarity Tester

- Gelatin Gel Strength Test System

- Bloom Viscosity Tester

- Thaw Tester

- Melting Point Tester

- Moisture Tester

- Transparency Tester

- Vacuum Constant Temperature Drying Case

- Transdermal Diffusion Tester

- Gelatin Freezing Strength

- Refrigeration & Cryogenic

- Life Sciences

- Laboratory

- Spectrometer

- Spray Dryer

- Rotary Evaporator

- Reactor

- Sterilizing & Cleaning

- Water Quality Analyzer

- Chemical Analysis

- Physical Testing

- Centrifuge

- Pathology Equipment

- Optical

- Ultrasonic Homogenizer

- Packaging Testers

- Compression Testing Machine

- Water Vapor Permeability Tester / Moisture Permeability Tester

- Air Permeability Analyzer

- Tearing Tester

- Heat Sealer

- Seal Tester

- Oxygen Permeability Tester

- Friction Tester

- Falling Dart Impact Tester

- Horizontal Impact Tester

- Pattern Thickness Tester

- Evaporated Residues Tester

- Inverted Pressure Sterilized Boiler

- Electronic Tensile Tester

- Heat Shrink Tester

- Leakage Tester

- Hot Tack Tester

- Disc Peeling Tester

- Roller Pressing Machine

- Sample Cutter

- Spectrodensitometer

- Hot Sticky Pull Tester

- NDT

- Agriculture & Food

- Hazardous Chemical Detection

- Fusion Machine

- Testing Chamber

- Filter Integrity Tester

- Petroleum & Oil Testing

- Industry Testing Device

- Featured

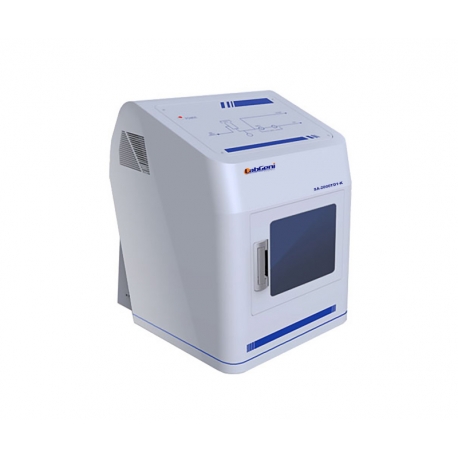

Auto True Density Analyzer

SI-2000TD1-K

SI-2000TD-K automatic open and closed porosity true density analyzer uses computer-controlled automatic operation of the gas expander true density analysis system, with a number of technology patents, the original test mode, can accurately determine true density, density and porosity of the powder, bulk solids, syrupy substance, foam and other materials,

- Remove this product from my favorite's list.

- Add this product to my list of favorites.

More info

SI-2000TD-K automatic open and closed porosity true density analyzer uses computer-controlled automatic operation of the gas expander true density analysis system, with a number of technology patents, the original test mode, so that a wider application area than similar instrument , can accurately determine true density, density and porosity of the powder, bulk solids, syrupy substance, foam and other materials,

Features and Benefits

- open closed porosity dedicated sample cell: a sample cell foam material specifically meet the national standard GB / T 10799-2008 and design, stainless steel, the interior space of a cube, can sample cell utilization rate (more than 80% of the national standard more than 15%), much higher than ordinary cylindrical sample cell;

- Test method: different volumes of sample cell as a sample test chamber "downloading" type of test mode, relative to similar instruments by filling way to change the way the test chamber volume, with the sample test chamber volume high utilization advantage, so that the test accuracy can be improved; "Bottoms bayonet," the sample cell, can meet the micro-volume and large volume sample loading demand convenience, in order to achieve the purpose of improving the accuracy of the test;

(Patent Title: having a sample cell directly as real test chamber densimeter Patent No.: 201120436207.5)

- Valve Type: gas control valves, fundamentally eliminate the solenoid valve structure similar instrument operation when the heat caused by the temperature change of the reference cavity and temperature non-uniformity, ensuring the ideal temperature effect; the use of software to subvert the fundamental Fixed way to reduce electromagnetic valve damage thermostat heating effect caused by error;

(Patent Name: precision pneumatic valve having a true density gauge patent number: 201220140709.8)

- modular manifold: no air passage between the modular structure, valves and valve pipe joints, reducing the leakage point, temperature field uniformity;

- Auto Repeat: You can automatically repeat the test until the specified accuracy;

- pressure balance: with automatic default, and the user selects a user-defined three modes of pressure equilibration time to adapt to the structural state of the sample do not;

- self-test process: advanced intelligent self-test process, intelligent judgment sample cell for leaks and instrument tightness is qualified to solve human error;

- restore normal pressure: a pressure test is completed automatically restore function to prevent splashing the sample;

- Control Interface: a clear image of graphical control interface, and can perform all operations on the hardware control interface;

- power protection: super stability, even if unexpected power outages, break, and will not lose the current data, and experiments recoverable proceed;

- Memory function: the instrument configuration parameters is written directly to the instrument hardware chip, stored permanently, and reinstall the system, do not worry instrument parameters are missing or incorrectly configured, to achieve zero artificial instrument hardware configuration parameters;

- Run Log: detailed running log instrument time accurate to the second, the log for the reliable operation of the instrument to provide protection and after-sale;

live voice: each test process real voice prompts;

- Multi-language package: support customizable editable multi-language interface;

- Remote Control: a network remote control function;

Performance parameters

- Test principle: expansion of the gas displacement method;

- Test content: true density; foam, rigid foam opening rate, closed porosity, holes opening ratio correction, aperture correction obturator rate cut; meet the national standard GB / T 10799-2008;

- Test accuracy: accuracy better than ± 0.04%, repeatability better than ± 0.02%, Resolution: 0.0001g / ml;

- Test volume range: 0.01 ~ 2000ml

- Test speed: Single Station 0.5-1min completing a test (without holding time). Double station double the efficiency analysis;

- Analysis stations: one analysis station, and a test sample;

- Scope: density of the sample size is not limited, the true density can be measured a variety of powder, granular, massive, like a foamy solid samples, as well as syrupy substance, and other non-volatile liquid sample; foam materials open closed porosity of the material;

- Test Volume: 0.01ml or more, for a variety of sample volumes; be equipped with micro-volume sample cell (with corresponding micro-cavity volume basis) for small samples; use directly as the test sample cell cavity patented technology, the sample volume is not test chamber volume restrictions;

- Double reference chamber: having built a reference chamber, an expansion chamber (expansion chamber for different sample cell volume to change the reference chamber volume to improve the measurement accuracy); program whether to enable the expansion chamber according to the remaining volume is automatically selected ; double reference cavity volume is to ensure a wide range of test accuracy;

- Pressure equilibration time: with automatic default, and the user selects a user-defined three modes of pressure equilibration time to adapt to the structural state of the sample do not;

- Pressure range: 0-1bar. Users can customize the maximum pressure, the pressure to reduce the error caused by deformation analysis of samples;

- Fully automated: a key to complete the circuit-switched and gas flushing, flushing the sample pretreatment system thermostat, repeated testing, gives the result;

- Thermostat mode: Automatic mode programmable thermostats, temperature accuracy error <0.1 ℃; programmable thermostat to control the process, and automatically enters the testing process;

- Sample cell: standard 10ml, 50ml, 150ml of the true density of the sample cell. Another also easily be extended to 2000ml (with automatic switching correspondingly large volume expansion chamber); Special requirements can be customized a variety of sample cell;

- Sample cell installation: Bottoms formula (patent pending number: 201120436207.5); to test the sample cell as a sample chamber, the sample test chamber has the advantages of high volumetric efficiency, so that the test accuracy can be improved; "Bottoms bayonet "type of sample cell to meet the needs of large volume sample loading, so as to improve test accuracy.

- Auto Repeat: You can automatically repeat the test until the specified accuracy;

- Self-test process: advanced intelligent self-test process, intelligent judgment sample cell for leaks and instrument tightness is qualified to solve human error;

- Test gas: 40 elevated pure helium, purity ≥99.999%; other gases such as nitrogen optional; not easy to use cylinders of environment, optional gas generator;

- Equipment accessories: patented modular gas control valve manifold; valves and pressure sensors of all imports;

- Appearance of the instrument: H610 * W450 * L550mm; 25kg