Spray Laser Diffraction

- Products

- Petroleum & Oil Testing

- Flash Point Tester

- Engler Viscometer

- Water Content Tester

- Kinematics Viscometer

- Distillation Tester

- Density Tester

- Rust & Corrosion Tester

- Sulphur Content Tester

- Acid & Alkali Tester

- Dropping Point Tester

- Demulsibility Tester

- Aniline Point Tester

- Ash Content Tester

- Low Temperature Tester

- Residue Carbon Tester

- Existent Gum Tester

- Vapor Pressure Tester

- Oxidation Stability Tester

- Foaming Characteristic Tester

- Bomb Calorimeter

- Octane & Cetane Analyzer

- Other Tester

- Tablet Drug Tester

- Dissolution Tester

- Disintegration Tester

- Tablet Hardness Tester

- Friability Tester

- Multi-Purpose Tester

- Clarity Tester

- Gelatin Gel Strength Test System

- Bloom Viscosity Tester

- Thaw Tester

- Melting Point Tester

- Moisture Tester

- Transparency Tester

- Vacuum Constant Temperature Drying Case

- Transdermal Diffusion Tester

- Gelatin Freezing Strength

- Refrigeration & Cryogenic

- Life Sciences

- Laboratory

- Spectrometer

- Spray Dryer

- Rotary Evaporator

- Reactor

- Sterilizing & Cleaning

- Water Quality Analyzer

- Chemical Analysis

- Physical Testing

- Centrifuge

- Pathology Equipment

- Optical

- Ultrasonic Homogenizer

- Packaging Testers

- Compression Testing Machine

- Water Vapor Permeability Tester / Moisture Permeability Tester

- Air Permeability Analyzer

- Tearing Tester

- Heat Sealer

- Seal Tester

- Oxygen Permeability Tester

- Friction Tester

- Falling Dart Impact Tester

- Horizontal Impact Tester

- Pattern Thickness Tester

- Evaporated Residues Tester

- Inverted Pressure Sterilized Boiler

- Electronic Tensile Tester

- Heat Shrink Tester

- Leakage Tester

- Hot Tack Tester

- Disc Peeling Tester

- Roller Pressing Machine

- Sample Cutter

- Spectrodensitometer

- Hot Sticky Pull Tester

- NDT

- Agriculture & Food

- Hazardous Chemical Detection

- Fusion Machine

- Testing Chamber

- Filter Integrity Tester

- Petroleum & Oil Testing

- Industry Testing Device

- Featured

More info

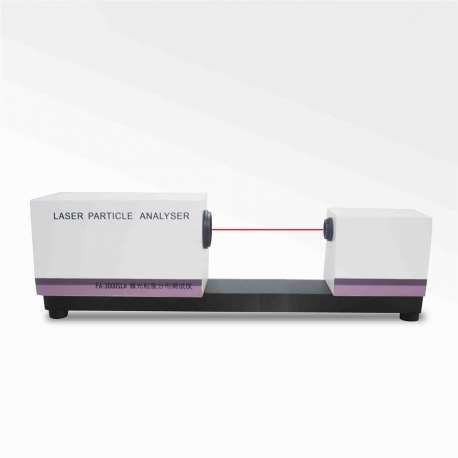

PA-3000SL (split type) spray laser particle size analyzer, full range Mie scattering theory and proprietary technology analysis and calculation, in line with international and other standard testing principles. Fully sealed metal case with good electromagnetic shielding and anti-interference performance.

Injectors, fire extinguishing nozzles, spray drying, aerosols, smoke, etc. To obtain accurate granularity data, fast sampling of the measured droplets, fast and representative testing, suitable for large-area large-volume objects , In order to make the auxiliary machine move left and right conveniently and quickly, the built-in camera automatic centering system. The entire testing process is automatically turned on / off under the control of a computer. The measured water mist, oil mist, smoke, etc. are quickly analyzed for particle size and other data. The unique precision mechanical structure achieves test repeatability, good stability and high resolution. Independent intellectual property rights can achieve the purpose of controlling product quality according to customer needs.

Application area

Specially designed for the measurement of droplet size, such as nozzle manufacturing, medical spray, water mist, smog, powder mist, aerosol production, research in scientific research institutions, etc.

Granularity test report shows

Software operation interface can choose Chinese or English as required. Multiple report forms: free distribution, normal distribution, RR distribution, etc. Content includes cumulative particle size distribution data and curves, interval particle size distribution data and histograms, typical particle size values such as D3, D10, D25, D50, D75, D84, D90, D97, volume average particle size and area average particle size and specific surface area And other data.

Practical case of spray laser particle size analyzer:

Instrument advantages

- The maximum distance between the main machine and the auxiliary machine can be adjusted within 10 meters, and the test position can be adjusted according to the site conditions. The nozzle (provided by the user) is connected to the gas supply pipe. The measured component is installed between the main machine and the auxiliary machine. The auxiliary machine moves to the best position left and right as required. Under computer control, the controller automatically inputs and disconnects the liquid or gas.

- Special technology algorithm, eliminating the impact of spray and host position changes on test results. The laser power is fully adjustable to suit very low and high concentration tests.

- The standard particle board is delivered randomly, and the instrument can be calibrated and verified at any time.

- Continuous automatic test, quick report once a second, continuous recording of multiple measurement results, with statistical comparison analysis function.

- Adopt full metal case, strong electromagnetic shielding performance. Reasonable mechanical structure makes the optical system stable and has strong anti-vibration ability

Technical Parameters

Model | PA-3000SL |

Measuring range | 0.1µm ~ 3000µm |

Repeatability error | ≤1% (deviation of national standard D50) |

Accuracy error | ≤1% (deviation of national standard D50) |

Signal light source | Imported semiconductor laser |

Host volume | Host: length 900 width 370 height mm270 |

Working power | AC220V ± 22V 50Hz ± 0.5Hz: |

testing time | 1 second / time, single or multiple automatic tests. |

Light path system | Parallel beam path, Fourier lens |

spacing | 1-10 meters (adjustable pitch) |

detector | 128 levels |

Auxiliary machine volume | Length 330 width 250 height 370mm |

Environmental requirements | Temperature: 5 °C ~ 35 °C; Humidity: <85%; |